Recycling Composites. Anywhere. Anytime

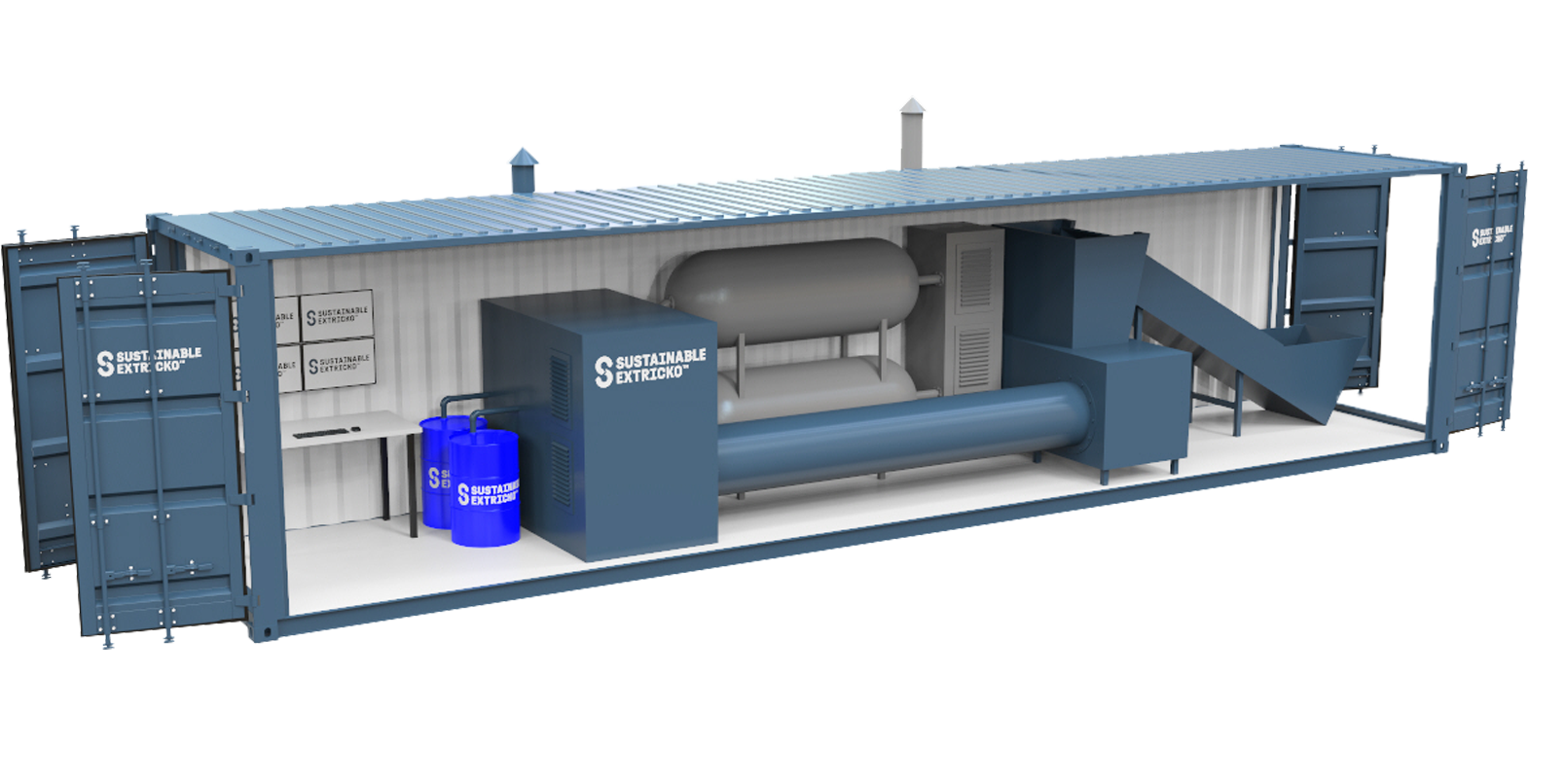

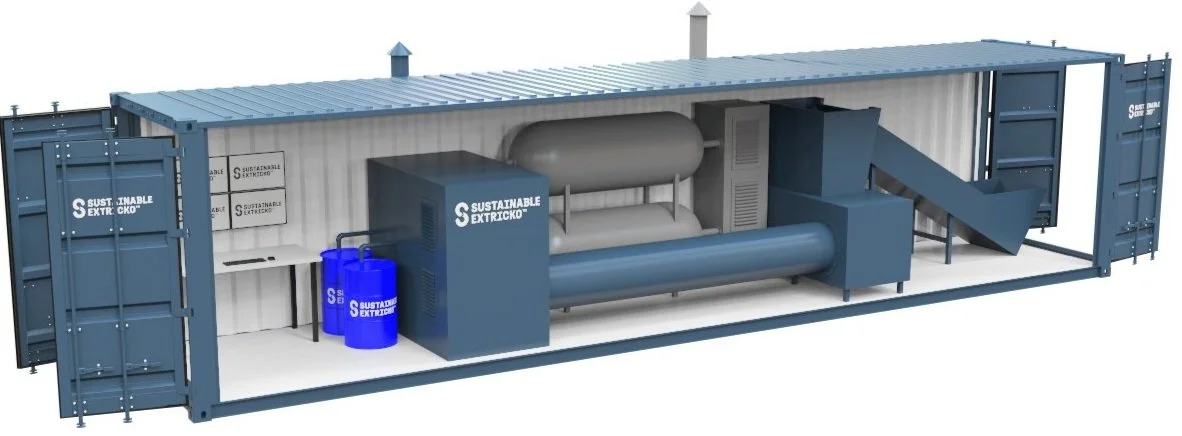

Sustainable Extricko's containerised recycling units bring

modular, closed-loop technology to your site,

turning waste into high-value materials.

The Future of Recycling

Recycling is evolving, and we're leading the way with adaptable, energy-efficient solutions designed to meet the needs of modern manufacturers.

Our containerized recycling units are built to optimize processing capabilities while reducing environmental impact. Scalable and efficient, they empower businesses to transform waste into opportunity—setting a new standard for responsible production. The future of recycling is here, and it's

smarter, cleaner, and more sustainable.

Key Stats

-

Our containerized recycling units are designed to optimize material recovery, drastically cutting down on landfill and disposal fees. By turning waste into a resource, manufacturers can significantly reduce their environmental footprint while lowering operational expenses.

-

Advanced processing capabilities ensure that up to 95% of recyclable materials are recovered efficiently. Our technology captures more usable material, minimizing waste streams and maximizing the value extracted from each cycle. This means less waste sent to landfill and more materials reintroduced into production.

-

Our units are engineered for energy efficiency, consuming significantly less energy than conventional recycling processes. Through smart design and innovative technologies, manufacturers can achieve their sustainability goals without compromising on performance.

-

Each unit is built to adapt to your processing requirements, allowing for seamless scalability as your recycling needs grow. Whether expanding capacity or introducing new materials, our modular approach ensures easy integration and minimal disruption.

-

Designed to meet international recycling and environmental standards, our units integrate smoothly into operations worldwide. From Europe to North America, our technology is compliant, future-proof, and ready to support sustainable manufacturing on a global scale.

Meet the Founders

At the helm of Sustainable Extricko are two brothers with a shared passion for sustainability and innovation. Dr Joe Penhaul Smith and Sam Penhaul have combined their unique skills and experiences to create a company that’s transforming the way industries approach waste.

-

The younger brother and professional sailor

Sam is a highly accomplished sailor and boat builder, having worked and built boats for prestigious teams including America’s Cup, RC44s and Vendee Globe teams.

His specialty is building teams and systems to capitalise on all of those marginal gains that race teams leave on the shelf. When combined with a talent for building novel composite components and developing recycled and bio-composite components, Sam is pushing forwards the limits of sailing

-

Joe Penhaul Smith, the older of the two brothers, is a professional scientist with over nine years of experience in biotechnology and green chemistry. With a PhD. focused on the intersection of industrial biotechnology and green chemistry, Joe has dedicated his career to translating laboratory innovations into scalable industrial solutions. His recent work includes collaborating with B&M Longworth, the original inventors of pressolysis, to further develop the revolutionary Extricko process. Outside of the lab, Joe remains connected to his passion for sailing, often found racing Europe Dinghies.

FAQs

-

Our recycling units are designed to be scalable, energy-efficient, and customizable to meet various processing capacities. This flexibility allows manufacturers to enhance their recycling processes without overhauling their existing operations, making sustainable practices more accessible than ever.

-

Yes, our units are designed with versatility in mind. We can tailor the processing capabilities to handle a wide range of materials, ensuring maximum efficiency and minimal waste for each unique application.

-

As global regulations tighten and consumer demand for sustainable practices grows, efficient recycling is more important than ever. Our containerized units help manufacturers stay ahead of the curve by minimizing waste, cutting costs, and reducing environmental impact—all while contributing to a circular economy.

-

Our units prioritize low energy consumption through advanced design and innovative technology. We also explore options for integrating low-carbon fuel sources to further reduce environmental impact, making recycling more sustainable and cost-effective.

We’re two brothers—a sailor and a scientist—on a mission to change the industry. Shocked that less than 1% of composites are recycled, we developed Extricko, a breakthrough in green chemistry that recycles every composite component with zero waste. We've proven it works and believe it should be the new industry standard. Our goal is to expand this technology across the outdoor world.

Shortlisted for the Moonshot Platform Start-Up award 2022

AWARDS

Shortlisted for the Maritime UK Start-up of the Year award 2024