Extricko Unveils New Containerized Recycling Units – A Step Towards On-Site Sustainable Waste Processing

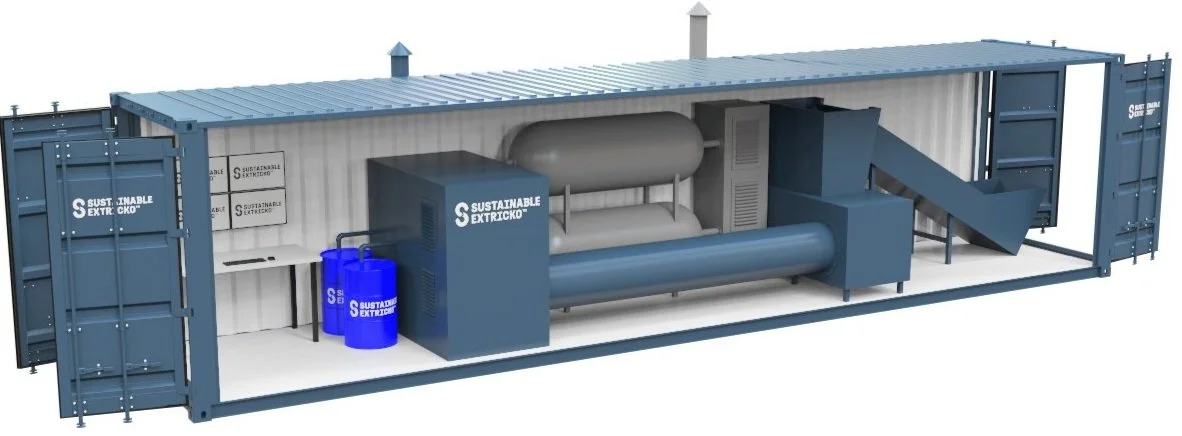

Extricko is excited to introduce its latest innovation—containerized recycling units designed to revolutionize how technical textiles and composites are recycled. Engineered for modular scalability and energy efficiency, these units allow for on-site recycling at manufacturing plants, industrial facilities, and recycling hubs, significantly cutting down on transportation costs and carbon emissions.

"We're bringing recycling to the source," said Sam, Co-Founder of Extricko. "Our containerized units give businesses the power to process waste right where it's generated. It's a practical step forward in making sustainable manufacturing not only achievable but also cost-effective."

The containerized solution is built on Extricko's innovative pressolysis technology—a superheated steam process that operates without harmful solvents and is designed to efficiently recover materials while maintaining a lower carbon footprint than traditional methods. By localizing the recycling process, Extricko is empowering manufacturers to take direct control of their waste, moving closer to a circular economy.

Joe, Co-Founder of Extricko, added, "We’ve always believed that sustainable recycling should be accessible and practical. These modular units allow us to meet businesses where they are—whether it's at a composite manufacturing facility, a recycling hub, or even on-site at production plants. It's about making sustainable choices easier and more effective."

Currently, Extricko is seeking funding to bring this groundbreaking technology to full-scale production. With the right partners, the vision of modular, containerized recycling units could become the new standard for sustainable waste processing